Categories Pastry Chef Articles

The phases of making pastry dough by Daniel Álvarez

In the book Sweet Devotion, which is now in its second edition, Daniel Álvarez gives puff pastry and brioche dough the gastronomic place it deserves. Throughout more than 200 pages of explanations, step-by-step photos, tips, and tricks, he covers popular European pastry specialties, from the croissant to the palmera and the mille-feuille, passing through kouglofs, panettone, and ensaimadas.

Available in a bilingual version (Spanish & English) in our Books For Chefs online bookstore, it is considered a reference manual for those who want to start or improve their technique in modern pastries.

Below we share the production phases that must be taken into account in pastry doughs and that Álvarez shares in this book in order to optimize the organization itself and obtain the best result, since depending on how a dough is handled, a completely different result can be obtained.

Kneading

One of the key moments in the entire preparation process is the kneading. It implies the beginning and the moment from which we must carefully monitor the state of the dough to manipulate it in one way or another depending on its state and our needs.

Although it seems obvious, before starting this process it is appropriate to have scaled all the ingredients that we are going to use, so that we are not forced to interrupt the preparation process at a crucial moment that could spoil the result. During my teaching work and as an advisor I have had to notice this on more than one occasion, that is why I prefer to highlight it.

The mechanical action that takes place during the kneading is of vital importance to mix all the ingredients and to confer to the dough the necessary conditions for an optimum development. At first, the flour will hydrate and absorb the rest of the ingredients to give way to the development of gluten. During this time, air is also incorporated, which favors oxidation, the development of aromas and the action of yeast.

The longer the kneading lasts, the more elastic the dough and the greater the air addition during fermentation. But an excess of kneading, however, would result in a very thin gluten mesh that when baked would develop exaggeratedly but that later would end up collapsing. By contrast, if the kneading time is lower, we obtain more rigid doughs, with smaller air cavities and a thicker result.

Once the gluten has developed, the fat is added, because with that action this development stops. On the other hand, if the fat is added from the beginning, the ingredients become ‘greasy’ and it is very difficult to reach the desired point, which also results in an undesired heating of the dough. This heating can activate the fermentation too early, and if it is excessive, it can melt the butter and prevent it from incorporating well, becoming poorly integrated and giving rise to a drier dough with a thick texture.

Temperature during kneading

Our doughs need strict temperature control. Normally, we will work with very cold ingredients to prevent the fermentation from starting too quickly or an acceleration of the development of the dough too early. The kneading temperature will always fluctuate between 23 and 24ºC.

Bulk rests in refrigeration

I strongly recommend bulk rests in the refrigerator or cold room. I like the texture the dough acquires and it gets ready for the next stage. They also contribute to the creation of a unique aroma, thanks to the development of organic acids.

The ideal temperature to control bulk fermentation is between 2 and 4°C. At lower temperature, there is hardly any fermentation. Above 5-6°C, on the other hand, the fermentation is accelerated in excess.

Lamination and shaping, fermentation and baking

The following stages of preparation have sufficient peculiarities to be approached separately in each case. Whether we talk about laminated doughs, to which we devote a specific introduction, or about brioche-type doughs, usually the forming stages come first, followed by the fermentation of the pieces, as long as they contain yeast. Fermentation at this point usually occurs, with some exceptions, at 26-28°C, with 75% humidity factor. Please learn more about the effect of yeast in the fermentation of the pieces in a previous section of this same introduction.

Brushing the pieces

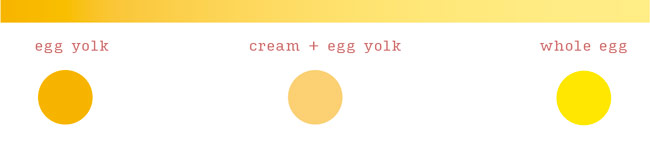

It is like the right make-up for every occasion. When we brush a dough before baking it, we seek to give a certain color to our product, a final aspect that enhances it. This coloration will be provided by the whole egg, the egg yolk separately, or a solution of yolk and cream.

We will use each of these ‘coatings’ according to the type of egg (even what the hens eat has an influence on the pigmentation), the type of dough and the type of oven. For example, if the baking time is shorter for a certain brioche dough, we will add yolk and cream rather than beaten whole egg, as we need to reach the desired coloration more quickly. In my case, usually a solution of yolk and cream, tailor-made, is the one that best suits the baking times I work with in order to reach the level of external coloration I desire.

Each professional should do their tests and adjust these parameters to get regularity in the result. And finally, the personal taste of each professional and that of their customers will also determine whether the coloration or goldenness of the final product should be more or less intense. At the same temperature and oven time, we will achieve a darker color in our products by using a higher proportion of egg yolk in the coating solution.

Solution for the coating of the pieces

775 g egg yolks

225 g cream

Baking

During the baking process, we will check if all the process carried out up to that moment has been the correct one, i.e. a well-developed dough, a controlled lamination and a fermentation that has given the adequate volume to each product.

In the oven, the fermentation cycle concludes when the dough reaches 55ºC. Also, the caramelization process of the sugar and the butter that the dough contains occurs, with the corresponding aromatic explosion that gives that unique personality to these products.

When taken out of the oven, many products made with croissant and brioche-type dough are brushed with an icing (80% sugar, 20% water) and placed back in the oven for a very short time, which will give us greater glossiness and an even more spectacular result.

Freezing

We start from the fact that avoiding freezing is already a guarantee of excellence in the final result of a product. However, we can use this resource at any stage of the preparation process (when bulk resting, halfway the lamination, before the final lamination, when the pieces have already been shaped, before baking) to optimize our production system. Of course, we will consider a number of considerations to minimize the damage that our frozen products may suffer.

In the book you will find some guidelines to preserve your frozen product in the best possible conditions.