Categories Pastry Chef Articles

Tips for choosing and working with chocolate according to The Pastry Alphabet

To continue pushing the limits of flavor and empowering the imagination of pastry chefs, the LAB, the creative department of Cacao Barry, developed a collection of practical and basic recipes based on the heritage of French pastry, which can be found in the book, The Pastry Alphabet.

Available in our online bookstore Books For Chefs, this book claims that it is necessary to master the basics to develop creativity. Which is why all its recipes are designed to make both traditional elaborations on a daily basis and for new creations.

The Pastry Alphabet, divided into four large blocks (biscuits, crèmes & mousses, glaçages, and pâtes), also has an interesting section dedicated to chocolate, which we share below.

Definition of chocolates

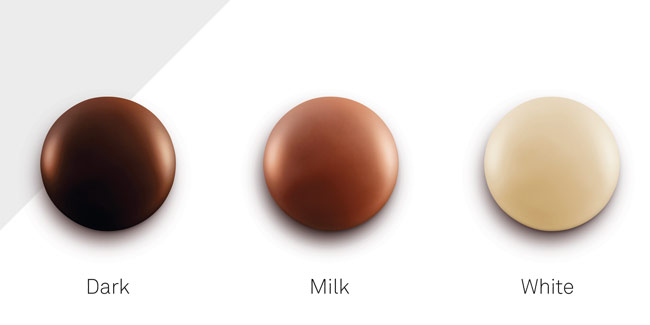

Dark

Dark chocolate is a mix of cocoa liquor, cocoa butter, sugar and vanilla Bourbon. The proportions of the different ingredients define the flavours which are limitless. Although beans selected will mainly define the aromatic profile, so does the recipe.

Milk

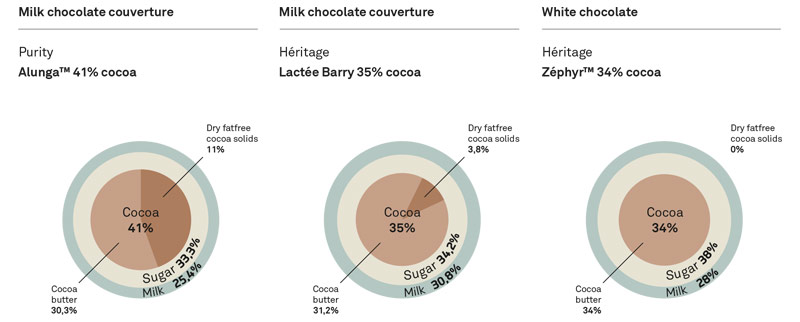

Milk chocolate is a mix of cocoa liquor, cocoa butter, milk powder, sugar and vanilla Bourbon. The proportions of the different ingredients can ensure an intense cocoa flavoured milk chocolate, a more creamy flavoured milk chocolate, or even a chocolate with a predominant caramel aroma.

White

White chocolate is a mix of cocoa butter, milk powder, sugar and vanilla Bourbon. It does not contain cocoa liquor. The proportions of the ingredients define the flavor that can result in a sweet, creamy or a caramel flavoured product.

The difference between chocolate and compound

Cacao Barry® chocolate is made from 100% pure cocoa butter. When a cocoa product contains other vegetable fats it is referred to as a compound coating.

The difference between chocolate and compound coating

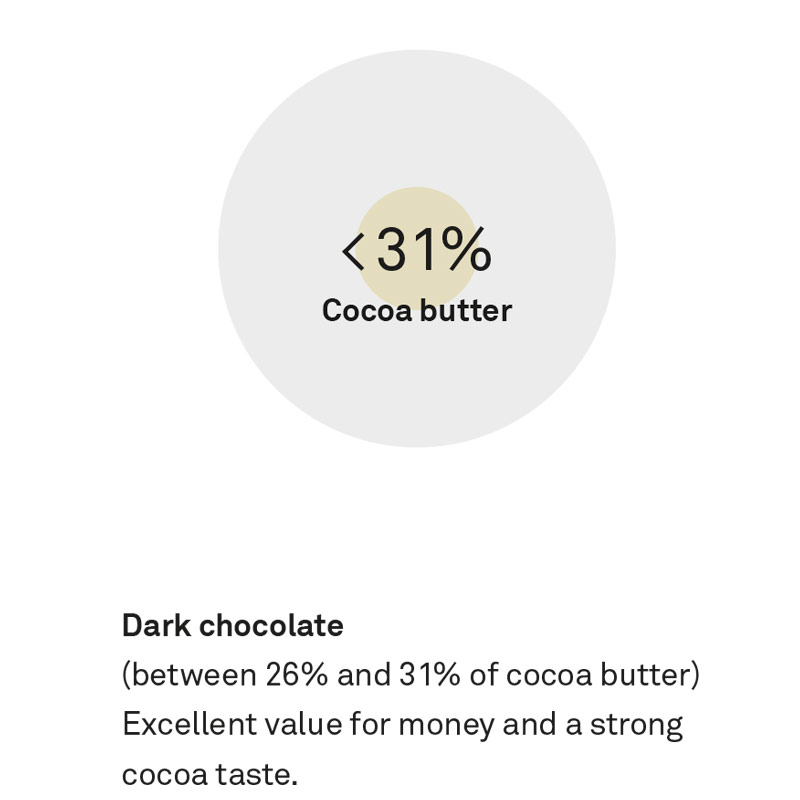

The difference between chocolate and chocolate couverture lies in the cocoa butter content, while both are excellent for professional use chocolate contains up to 31% cocoa butter and is ideal for making chocolate mousses, ganaches, praline fillings, etc.

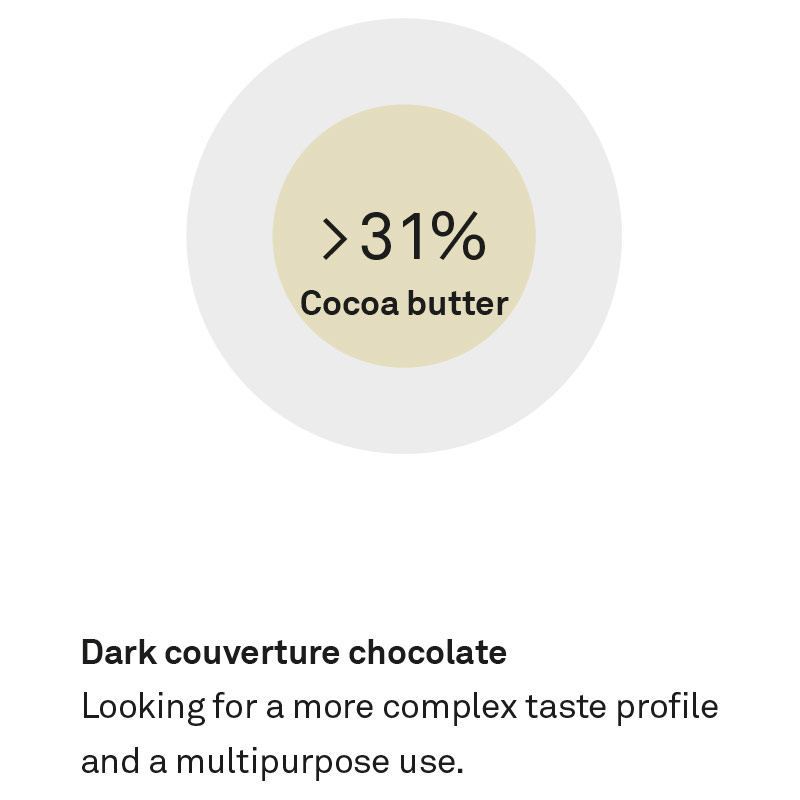

A chocolate couverture contains over 31% cocoa butter. Its high fat content makes it ideal for toppings, moulding and pastry.

How to choose a chocolate?

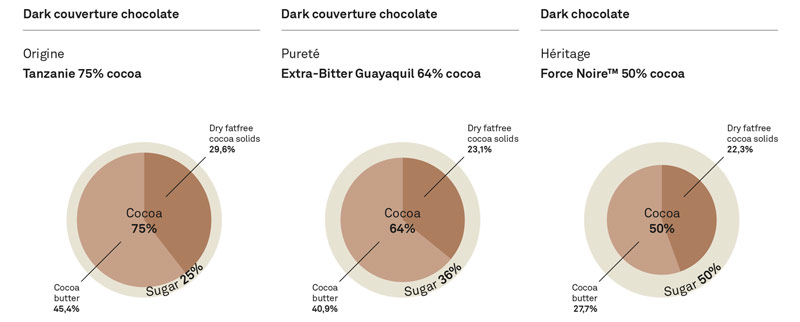

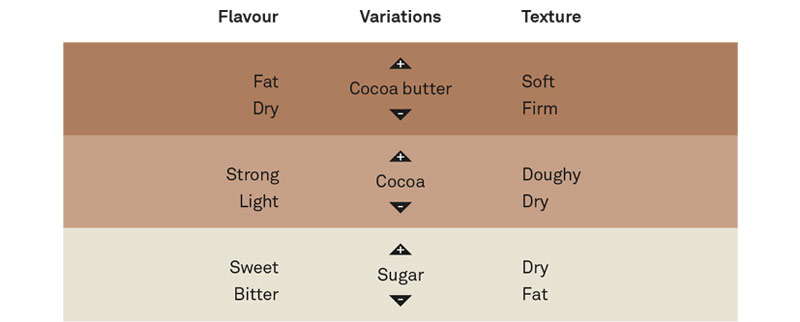

The differences in taste and texture are directly related to the composition of chocolate, each ingredient has an impact.

The chocolate’s taste is determined by the proportion in the recipe of dry solid products: cocoa (the most important), milk, sugar and vanilla solids.

The total fat content total in Chocolate (cocoa butter and eventually milk fat) determines its fluidity or viscosity.

Examples:

Where do the flavors come from?

Sensory descriptors of where chocolate comes from::

- The origin and variety of cocoa

- The process

- The chocolate recipes

The origins and varieties of cocoa

Origins of cocoa

Each origin produces cocoa beans with a different taste profile.

In general:

- The Latin American beans offer fruity and/or spicy notes.

- The African beans give chocolate body.

- The Asian beans reveal an acid accent.

Varieties of cocoa

The botanical variety of cocoa will also influence the flavour of chocolate.

There are 3 botanical varieties of Theobroma cacao and each has a typicity of taste recognized:

Criollo

- Criollo means “local” in spanish. Discovered in Mexico. Trees have low yield and are really fragile.

- Availability: 5 to 8% of cocoa beans are Criollo variety.

- Geography: Central America / Asia

- Description: Fine cocoa, very aromatic and low bitterness.

Forastero

Forastero meaning “stranger”, was discovered in Venezuela. Hearty trees with good yield. A majority has a shape called Amelonado.

- Availability: 75 to 80% of cocoa beans are Forastero variety.

- Geography: Africa / Brazil

- Description: Strong cocoa taste, bitter and slightly acidic.

Trinitario

Trinitario (from word Trinidad, where it has been developed) Hybrid of Criollo and Forastero. Trees have high yield with quite aromatic profile.

- Availability : 15% of cocoa beans are Trinitario variety.

- Geography: All over the world

- Description: Fine cocoa. Slightly aromatic.

Process

From bean to cocoa liquor

Fermentation

Fermentation takes from 3 to 7 days. It enables the development of aroma precursors and also the compound bitterness and astringency.

Drying

Sun drying should be done according to good agricultural practices to avoid undesirable tastes. Poor drying will cause such musty tastes. Wood-fire drying or by other combustibles can leave smoky flavour traces, more or less intense.

Roasting

Roasting enables the development of characteristic cocoa aromas (warm notes).

From cocoa liquor to chocolate

Refining

Grinding is important because it will determine the particle size, which influences the perception of taste. Fine particles give long lasting taste and smooth mouth feel.

Conching

Conching will finalize the taste development. A long conching will give more smoothness and rounded taste. Low temperature preserves the characteristic notes as fruity or sour notes. High temperature for a milk chocolate creates caramelized notes, also biscuit, slightly toasted.

The Chocolate Recipe

Finally, the composition of a chocolate recipe will influence the final taste. Proportions of cocoa liquor, cocoa powder, cocoa butter, sugar, milk, flavorings, etc. play an essential role in the taste of the final recipe.

Useful information about chocolate

How to melt chocolate

- At a temperature between 40 and 45°C.

- Use a melter or a bain-marie.

How to cool chocolate

- Moulded products: Cool at a temperature that is around 10°C lower than the working area: about 8 to 12°C.

- Enrobed items: Keep cool at a temperature of 14-18°C.

How to store chocolate

- Free from light..

- In a clean dry space, free from odours.

- At a constant temperature between 12 and 18°C.

How to temper chocolate

Tempering chocolate is pre-crystallizing the cocoa butter in chocolate. It ensures the chocolate to become hard and shiny during cooling. Good tempering also guarantees moulded chocolate products to be easily removed from the moulds after cooling.

Classic tempering with Cacao Barry® Pistoles™

- Melt the chocolate at 40-45°C.

- Add 15-20% Pistoles™ and stir.

- Allow the chocolate to cool to 30-32°C.

- Chocolate is ready to process.

Wheel-type tempering machine

- Melt the chocolate in the wheel machine at 40-45°C.

- Once melted, lower the thermostat. To 32°C for dark or 30°C for milk or white chocolate.

- Add 15% to 20% of Pistoles™. The machine mixes the Pistoles™ –and their crystals– into the melted chocolate.

- Chocolate is ready to process.

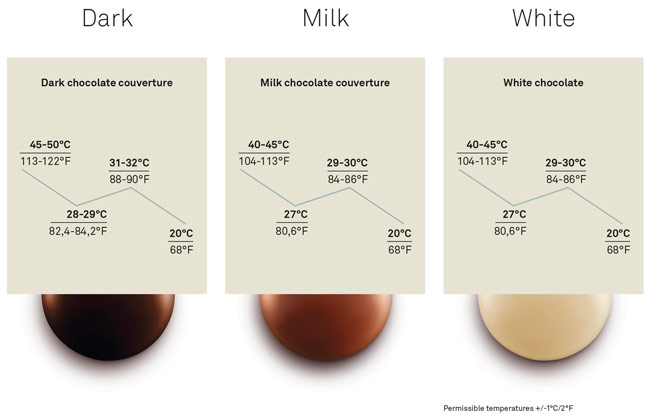

Tempering curves:

Tempering in the microwave

- Pour Pistoles™ in a bowl.

- Melt in the microwave.

- Take the Pistoles™ out of the microwave every 15 to 20 seconds and stir well to ensure they do not scorch.

- Repeat until all Pistoles™ have almost melted. Only some small pieces should still be visible.

- Remove from the heat and stir well until also the last pieces have melted and the chocolate has slightly thickened. Chocolate is ready to process.

Tempering on a cool (marble) work surface

- Melt the chocolate at 40-45°C.

- Pour 2/3 of the chocolate on the marble.

- Move continually.

- Continue until the chocolate thickens.

- Add back again to the rest of the melted chocolate.

- Stir well. Chocolate is ready to process.

Tempering the chocolate is very simple, thanks to Mycryo® cocoa butter

- Melt the chocolate at 40-45°C (in microwave or bain-marie).

- Allow the chocolate to cool at room temperature to: 34-35°C for dark chocolate, 33-34°C for milk, white or coloured chocolate.

- Add 1% of Mycryo® cocoa butter, or 10 g for 1 kg of chocolate.

- Mix well. Chocolate is ready to process.

Easy tricks to work with chocolate

Difficult to remove from mould

Cause

- Poorly tempered chocolate couverture.

- Cooling temperature too high.

- Layer of chocolate couverture too thin.

- Mould not cleaned sufficiently.

Solution

- Crystallising the chocolate couverture properly..

- Good tempering is easy with Pistoles™.

- Once moulded, the mould temperature should be between 14-16°C for easy demoulding.

- Use a less fluid chocolate couverture for bigger moulded figures.

White or grey colorationnull

Cause

- Too slow cooling of chocolate couverture.

- Poorly tempered chocolate couverture.

- “Over-crystallized” chocolate couverture

- Mould too cold when chocolate couverture retracts.

Solution

- Cooling should occur at a temperature approx. 10°C lower than the ambient temperature.

- Good tempering is easy with Pistoles™.

- Melt the excess crystals by increasing the temperature gradually by 0.5°C.

- Mould temperature should be 20 to 24°C before demoulding.

Cracks in moulded product

Cause

- Refrigerator too cold.

- Layer too thin and cooling too fast.

Solution

- Mould temperature should be 14-16°C before demoulding.

- Use a chocolate that has the right viscosity for the mould (for small mould, use a fluid chocolate and for large mould use a chocolate with a good viscosity).

Dull stains on moulded products

Cause

- “Over-crystallised” chocolate.

- Refrigerator too cold (ideal temperature is between 14-16°C).

- Moulds too cold.

- Moulds not cleaned sufficiently.

Solution

- Melt the excess crystals by increasing the temperature gradually by 0.5°C.

- Mould temperature should be 20 to 24°C before demoulding.

- Clean moulds!

Thickening of couverture while working

Cause

- Excessive crystallisation of chocolate couverture.

Solution

- Increase the temperature gradually by 0.5°C.

- Do not add cocoa butter.

Moulded products are not glossy

Cause

- Chocolate couverture too cold when filling the moulds.

- Workshop or refrigerator too cold.

Solution

- Chocolate temperature during the filling of the moulds should be around 20°C.

- Ambient temperature should ideally be 18° to 22°C.

- Follow the advised temperature for tempering.

Fingerprints on finished product

Cause

- Product touched with wet or warm fingers.

Solution

- Do not touch the product with wet or warm fingers. If necessary, gloves should be worn.

Dirty moulds

Cause

- Fingerprints inside the mould.

- Moulds contaminated by fillings.

- Dull stains in the mould..

- Poorly tempered chocolate used.

- Moulds not pre-heated.

Solution

- Clean moulds using warm water and a very mild detergent.

- Use a very soft cloth, a sponge or brush in order to avoid scratching the inside of the moulds. Rinse with warm water and remove remaining water with a dry cloth. Once rinsed, you can also use a compressed air pistol to dry your mould.

- Good tempering is easy with Pistoles™.

- Moulds should ideally have a temperature of 20°C (preheat a little).