Categories Pastry Chef Articles

How to improve the use of cocoa powder in pastry according to Talia Profet and deZaan

In their book Know Cocoa, deZaan shares the endless possibilities of cocoa powder, with professional chefs. A world-renowned producer of premium cocoa products with over 110 year of history, deZaan offers a wealth of tips, cocoa cooking suggestions and recipes in their new book. Know Cocoa explains the intricacies of cocoa ingredients, and gives details on it’s interesting range of cocoa powders.

Below, we review some of the sections of this practical and useful manual from Talia Profet, deZaan’s European Chef Lead. Talia has worked as a pastry chef in Michelin-starred kitchens all over the world. She currently spends her time creating, testing and tasting recipes using deZaan’s cocoa ingredients, to ensure that all artisans and chefs have access to the latest tips, insights and innovations.

From Cocoa Beans to Cocoa Powder

1. Cocoa beans

The cocoa bean starts its life as a seed inside a cocoa pod, which grows directly from the trunk of the tree Theobroma cacao. After the pods have been harvested, the beans are scooped out and taken to be fermented. Fermentation develops the complex organic components that define the final taste of cocoa. The method varies depending on the region. In much of West Africa, cocoa beans are piled on the ground, then covered with banana leaves and left for 4 to 7 days. By contrast, regions with more rainfall must use fermentation boxes and specially built fermentation centers. Once fermented, the cocoa beans are dried for several days, often in the sun but sometimes using artificial driers. They are then graded and transported to a factory for processing.

2. Cocoa nibs

This begins with three steps: cleaning, to remove foreign materials or imperfect beans; breaking, to separate the shell and then break the beans into smaller pieces; and winnowing, which uses airstreams to remove the shell. The objective is to obtain clean, broken, deshelled kernels, known as nibs. Next the nibs are sterilized with steam or during roasting depending on the process and product type. The nibs are optionally Dutched depending on the product type (natural cocoa powders don’t undergo Dutching). Dutching, also known as alkalizing, involves treating the nibs with an alkali solution such as potassium carbonate. This will produce a cocoa powder with a chocolaty flavor and a darker color. Flavor and color are further developed by roasting. Temperatures range from 95 to 145°C (200-295°F) depending on the process, equipment, type of nib, and preference.

3. Cocoa mass

After roasting, the nibs are ground into cocoa mass, also known as cocoa liquor or cocoa paste. Grinding is a multistage process where the nibs are converted from a solid to a fluid mass of cocoa particles suspended in cocoa butter. This happens because about half of the cocoa bean is made of cocoa butter (or fat) and the grinding breaks down the cell structures, and releases the cocoa butter, creating a liquid product. This cocoa mass is either supplied to a chocolate manufacturer for producing chocolate or sent to a hydraulic press to produce cocoa butter and cocoa powder.

4. Cocoa powder and cocoa butter

The hydraulic press exerts a pressure on the cocoa mass as high as 450kg/cm2, which will partially extract the cocoa butter. It’s impossible to remove all the butter and around 10-24% remains, depending on preference. This product is called cocoa cake, which is later pulverized into a fine powder and then cooled gradually through a tempering process. This, finally, is how cocoa powder is crafted.

Cocoa Powder: The Six Elements

When comparing cocoa powders there are six elements to consider. Talia Profet goes over them in detail starting with deZaan’s collection of seven cocoa powders: True Gold, True Dark, Terra Rossa, Rich Terracotta, Crimson Red, Carbon Black, and Rose Blush.

1. Color

Whether brown, black, or red, color is determined by several factors; the cocoa beans, the length and quality of fermentation, the level and type of Dutching, and the length and temperature of roasting.

A distinctive characteristic of cocoa powder is the difference between its dry (extrinsic) color and its wet (intrinsic) color. For the dry color, look at an unmixed powder. For the wet color, look at a powder that has been combined with a liquid substance such as water, dairy, or fat. Here are examples of how color can vary between intrinsic and extrinsic, specifically when mixed with water. Note on the right how True Dark is lighter than True Gold when dry, but then darker when wet. This is an optical effect created because True Gold is higher in fat (21% vs 11%), which impacts how light is absorbed and reflected.

Also note how dark Carbon Black becomes when wet. Carbon Black is Dutched at the nib stage (as opposed to at the cocoa cake stage), which means that it is lighter when dry than other black powders. However, this effect is dissipated when wet. The advantage of Dutching nibs rather than cake is that the taste is far superior.

2. Flavor

The flavors of cocoa powder vary from chocolaty through to fruity, nutty, and salty. Generally, Dutched cocoa powders have a more mellow, chocolaty taste whereas natural powders have more pronounced acidic, floral, and fruity notes. The deZaan range provides the full spectrum of cocoa flavors.

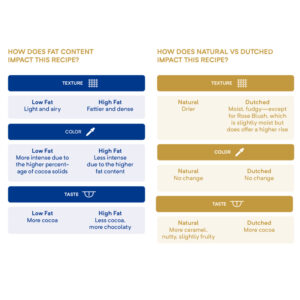

3. Fat Content*

Cocoa powder is what remains after grinding the nibs and hydraulically pressing out much of the cocoa butter (fat). It is generally either highly defatted (0.5%), low fat (10-12%), or high fat (20-24%). Higher-fat cocoa powders provide a richer mouthfeel and a longerlasting flavor in comparison with low fat cocoa powders. However, low fat cocoa powders provide a more intense cocoa flavor than higher fat powders due to the percentage of cocoa solids. Highly defatted cocoa powders witha fat percentage of at 0.5% lend themselves well to meringues, macarons, sorbets and reduced fat applications such as dry cookies and puff or flaked pastry.

*The way cocoa powders are formally labeled and the nomenclatures used on such labeling and other technical documents provided at point of sale depends on the applicable food regulations in different countries. In this booklet “low fat” describes cocoa powder containing less than 20% cocoa butter (generally 10-12% cocoa butter) and “high fat” describes cocoa powder containing more than 20% cocoa butter (generally either 20-22% or 22-24% cocoa butter). Where you see the term “highly defatted”, this refers to the deZaan Rose Blush cocoa powder, which has a cocoa butter content of 0.5%.

4. Dutching

The Dutching process, also known as alkalization, involves treating cocoa nibs with an alkaline solution. This mellows the acidity, enabling the cocoa’s deep flavors to emerge, and generally leads to a darker or redder powder. Heavily Dutched powders have a pH of around 8 and natural cocoa powders a pH of around 5. This change in pH can impact a recipe significantly. For example, a low pH value is acidic, so natural cocoa powders will react with the baking soda to produce bubbles, creating products that are lighter and airier.

5. Water Absorption

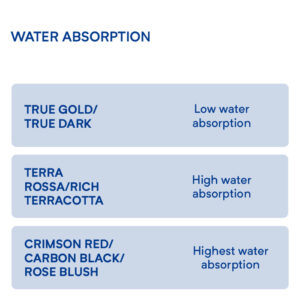

Cocoa powder is an ingredient that is hydrophobic (or water-hating). It is not soluble but will absorb moisture—dependent on the pH value of the powder. In some cases, a higher pH value absorbs more moisture than a lower pH value. This is important to understand when considering how much liquid or cocoa powder to add to a recipe. For example, adding the same quantity of water to True Gold and Carbon Black will create very different textures; a paste made from Carbon Black will be much thicker. (See table)

6. Proteins & Dietary Fiber*

It is important to consider the specific protein and fiber content of each cocoa powder as they vary throughout the range. Understanding this enables you to be more accurate when calculating how much additional protein or fiber to add or remove in recipes such as in ice cream or when converting a recipe to be vegan. Note that protein levels are higher in low fat cocoa powders due to the lower fat percentage. (See table)

*Note that both protein and dietary fiber levels can vary by production run and the values listed in the table should only be used as indicative.

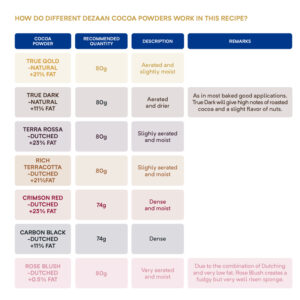

How do different Dezaan cocoa powders work in this sponge?

Here Profet explores how different cocoa powders, fat content, and natural drier/dutched impact in this sponge recipe.

Sponge

- 380 g flour

- 74-80 g deZaan cocoa powder

- 2 g baking powder

- 1 g salt

- 460 g butter

- 460 g granulated sugar

- 400 g eggs

Sift all the dry ingredients together except for the sugar. Set aside. Cream the butter and sugar until pale and fluffy. Gradually add the eggs, mixing thoroughly after each addition. Fold in the dry ingredients until just combined. Bake at 170°C/338°F for about 30 minutes.

Notes: If using baking powder or baking soda, please see the guidance under General Baked Goods.

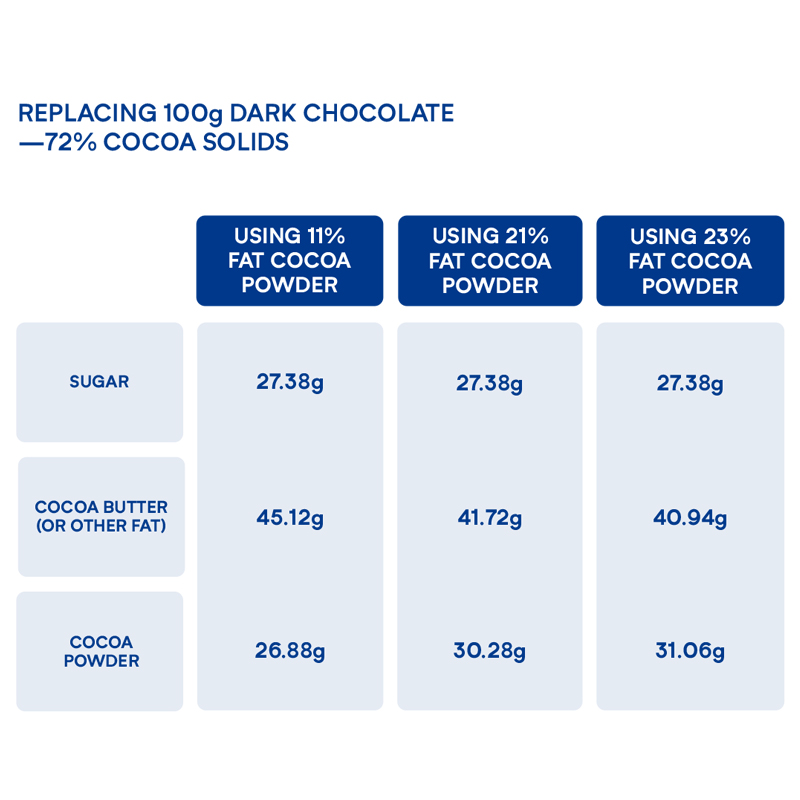

How to Convert a Recipe from Chocolate to Cocoa Powder

If you’re considering converting a tried and tested recipe from chocolate into cocoa powder, you might want to know what quantities of ingredients you need. The first thing to consider is the type of chocolate and its percentages of fat, cocoa solids, and sugar. Once you have those quantities, it’s just a few simple steps to reverse-engineer the recipe to achieve the same characteristics.